Camdent Dental Milling Machines

Camdent

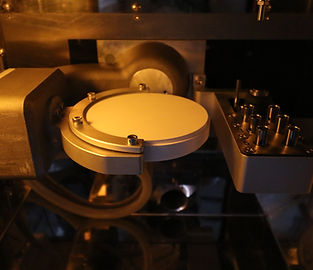

CDM5Z

New Appearance

5-Axis

Dry-Milling Machine

Overview:

CDM5Z is a 5-Axis dry-milling machine for dental CAD/CAM system with wide range of materials, featuring high accuracy, durable stability and excellent compatibility. It is an ideal choice for high-precision restorations including bridges, frames, splint, abutment,base and complicated operations like zirconia perforation. Equipped with premium spindle, imported core parts, smart CAM nesting system and intelligent touch screen, CDM5Z offers better disc handling, wider material capabilities, automatic tool change to deliver a higher efficiency.

Key features:

1. Compact structure

compact size 620mm*500mm*650mm

2. Box structure

High rigidity, not easy to deformation

3. Comprehensive alarms of the protections

Low pressure of the air cooling: low pressure of the changing,unsuccessful returning the knife,breaking the bur when cuts,wrong type of the burs.

4. Open controller system

This system supports international ISO standard G code, compatible with popular CAM software, such as Hyper Dent, millbox, WorkNC dental, etc.

5. Intelligent processing

.jpg)

Camdent CDM5G

5 Axis Wet/Dry

Dental Milling Machine

The CAD/CAM digital lab solution

Overview:

CDM5G is a very cost-effective 5-axis dental milling machine suitable for dental clinics or dental laboratories. It supports dry and wet cutting and can efficiently work with zirconia, titanium and premill , glass ceramics, PMMA, PEEK, wax and other materials, and equipped with a multi-functional clamp, it is compatible with 98mm and 98.5mmdiameter discs, C14 Glass Ceramics, Arum and Medentika titanium premills.

Key features:

1. Multifunctional Control System

Supports remote diagnosis and control management, Wifi and Lan network connections, network file transmission, intelligent detection of broken tools, breakpoint resume miling function, tool life management, Automatic detection and calibration functions. And compatible with Hyperdent and SUM3D MilBox.

2. Intelligent processing

Excellent and simple man-machine interface, touch screen control, simple operation, unique CAD/CAM processing strategy, no need for professional CNC programmers, one-button operation, stable operation.

3. High Accuracy

The body structure adopts the industrial standard cast iron and cast aluminum structure, high rigidity, no deformation, stable precision, long service life. The mechanical transmission part adopts Taiwan/Germany C3 grade high precision ball screw and P grade linear guide rail.

4.Automatic switching between wet and dry mode

Using original wet and dry separation technology, it can automatically switch between dry and wet states during processing.When miling zirconia materials, the vacuum cleaner works automatically and the wet cutting state automatically turns off.

5. High Efficiency

It adopts high power frequency conversion and high speed tool changing spindle with large torque, high precision, and it can process various materials with high efficiency.

6. Automatic calibration function

.jpg)

.jpg)

Camdent SDM5T

New Appearance

All-In-One

5 Axis Wet/Dry

Dental Milling Machine

The CAD/CAM digital lab solution

Overview:

SDM5T is a 5-Axis dry-milling and wet milling machine for dental CAD/CAM system with wide range of materials, featuring high accuracy, durable stability and excellent compatibility. It is an ideal choice for high precision restorations including bridges, frames, splint,abutment, base and complicated operations like zirconium perforation. Equipped with premium spindle, imported core parts, smart CAM nesting system and intelligent touch screen, SDM5T offers better disc handling, wider material capabilities, automatic tool change to deliver a higher efficiency.

Key features:

1. Multifunctional Control System

Supports remote diagnosis and control management, Wifi and Lan network connections, network file transmission, intelligent detection of broken tools, breakpoint resume miling function, tool life management, Automatic detection and calibration functions. And compatible with Hyperdent and SUM3D MilBox.

2. Intelligent processing

Excellent and simple man-machine interface, touch screen control, simple operation, unique CAD/CAM processing strategy, no need for professional CNC programmers, one-button operation, stable operation.

3. High Accuracy

The body structure adopts the industrial standard cast iron and cast aluminum structure, high rigidity, no deformation, stable precision, long service life. The mechanical transmission part adopts Taiwan/Germany C3 grade high precision ball screw and P grade linear guide rail.

4. Double side support at A and B axis.

strong rigidity,The tool does not rebound during high intensity cutting.

5. High Efficiency

It adopts high power frequency conversion and high speed tool changing spindle with large torque, high precision, and it can process various materials with high efficiency.

6. Automatic calibration function.

Dental Milling Machine Packages Available

.jpg)

.png)